Hi-MO X6 Max Explorer LR7-54HTH

|

Up to 615 W |

Up to 22.80 % |

15 Years

|

25 Years

|

|

Module Power

|

Module Efficiency

|

Product Warranty

|

Power Warranty

|

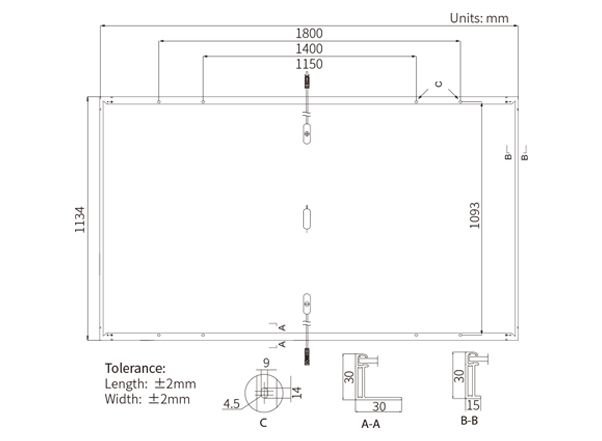

Mechanical Parameters

| Layout | 108(6X18) |

|

|

Junction box |

Split junction box, IP68

|

|

| Weight |

21.6kg

|

|

| Size |

1800X1134X30mm

|

|

| Packaging |

36 pcs./pallet

216 pcs./20GP

864 pcs./40HC

|

Electrical Performance Parameters (STC Test)

| Module model | LR7-54HTH-455M | LR7-54HTH-460M | LR7-54HTH-465M |

|---|---|---|---|

| Maximum power (Pmax/W) | 455 | 460 | 465 |

| Open-circuit voltage (Voc/V) | 39.15 | 39.35 | 39.55 |

| Short circuit current (Isc/A) | 14.79 | 14.86 | 14.93 |

| Peak power voltage (Vmp/V) | 32.98 | 33.19 | 33.39 |

| Peak power current (Imp/A) | 13.80 | 13.86 | 13.93 |

Electrical Performance Parameters (NOCT Test)

| Module model | LR7-54HTH-455M | LR7-54HTH-460M | LR7-54HTH-465M |

|---|---|---|---|

| Maximum power (Pmax/W) | 340.0 | 343.7 | 347.4 |

| Open-circuit voltage (Voc/V) | 36.76 | 36.95 | 37.13 |

| Short circuit current (Isc/A) | 11.95 | 12.00 | 12.06 |

| Peak power voltage (Vmp/V) | 30.09 | 30.29 | 30.47 |

| Peak power current (Imp/A) | 11.30 | 11.35 | 11.41 |

Mechanical Load Capacity |

Temperature Coefficient (STC test) |

|||

| Maximum static load on the front (such as snow and wind) | 5400Pa | Temperature coefficient of short circuit current (Isc) |

+0.050%/℃

|

|

| Maximum static load on the back (such as wind) |

2400Pa

|

Temperature coefficient of open circuit voltage (Voc) |

-0.23%/°C

|

|

| Hail test |

Diameter 25 mm, impact speed 23 m/s

|

Temperature coefficient of peak power (Pmax) |

-0.29%/°C

|

|

FAQ

The Hi-MO X6 Artist (Ultra Black) product is a new product launched by LONGi under the Hi-MO X6 series, targeting the global distributed household high-end market. Hi-MO X6 is consisted of four series, namely: The “Explorer”series, represents “Classic Choice” The “Scientist”series,represents “Ultimate Efficiency” The “Guardian”series,represents “Functional Enhancement” The “Artist”series, represents “ Technology leads aesthetics” Hi-MO X6 Artist (Ultra Black) product is a new product under Hi-MO X6 Artist series.

The main advantages of LONGi’s TaiRay wafers released in March 2024 compared to other products in the market are: 1. High resistance concentration, high efficiency cell staging is more concentrated after being made into a cell, and it is easier to find the median resistivity of the most suitable cell through the process; 2. The use of new processes to reduce the content of oxygen and other impurities, crystal growth defects less, improve the efficiency of the cell; 3. The new process improves the mechanical properties of silicon wafers, which improves the yield rate of cells and modules in the production process, reduces the risk of potential hidden cracks, and improves reliability, so modules equipped with TaiRay wafers will also have better performance in terms of reliability.

LONGi believes that in the face of diversified technological routes, what customers really want is a module product that can use innovative and cutting-edge technologies, have leading performance in all dimensions, and at the same time be able to operate safely and reliably. Therefore, LONGi follows the first principle to deconstruct the module products at the industry chain level, and believes that silicon wafers and cells together determine the product performance of PV modules, in which the core focuses of cell technology should include efficiency, degradation performance and welding structure, etc., and the core focuses of wafer technology should include mechanical strength, resistivity and minority carrier life. LONGi has already launched LONGi’s self-developed hybrid passivation HPBC high-efficiency cell technology in October 2022, which has differentiated advantages in cell efficiency, degradation performance and welding structure. And LONGi has launched the new TaiRay wafers in March 2024, which also has platform advantages, breaking the dilemma of homogeneous competition in the monocrystalline silicon wafer industry, and possessing multiple advantages over traditional RCz wafers in terms of resistivity fitness and concentration, long minority carrier life and high mechanical strength. The release of Hi-MO X6 Max is the first time that TaiRay Inside and HPBC cell technology have joined forces, achieving another breakthrough at the technical level and achieving the effect of “1+1>2”, with a comprehensive improvement in module efficiency, degradation parameters and mechanical performance.

Due to the larger size, in order to ensure the safe and reliable operation of the module after installation, the mounting method of Hi-MO X6 Max has been changed compared to Hi-MO X6. Specifically, Hi-MO X6 Max will have a difference in the position of the mounting block compared to Hi-MO X6, and the bolt position will remain the same, refer to the “LONGi Distributed Photovoltaic Module Installation Manual” for the specific installation method.

The new dimensions of Hi-MO X6 Max components are: 72 version: 2382*1134mm; 54 version: 1800*1134mm. In addition to promoting industry standardization and reducing upstream and downstream losses and risks, this switch in dimensions will significantly reduce customer costs and increase customer revenues. In terms of reducing customer costs, take the 72 version as an example, Hi-MO X6 Max module can effectively reduce transport costs by about $0.61/kW compared with conventional Hi-MO X6 module products, improve the use of 40HC containers by 4.4%, and realize 98.5% container utilization; at the same time, due to the power enhancement, the BOS cost of the system installation side is reduced by 3.57% (about $4.16/kW) in the comparison of the same mainstream power grade (585W vs. 615W). In terms of increasing customer revenue, take the 72 version as an example, compared with the same module specification products of friends using 210R wafers, Hi-MO X6 Max module products using M11 wafers have lower current, which can effectively reduce the loss of current transmission cable by 9%, and increase power generation revenue by 0.1%; at the same time, due to the larger size of the 210R wafers, the crystal pulling process is more difficult to control, and it’s more likely to introduce impurities to form concentric circles with oxygen impurities. At the same time, due to the larger size of 210R wafers, it is more difficult to control the crystal pulling process, making it easier to introduce impurities and form concentric circles of oxygen impurities, which affects the long-term stability of power generation of modules.

In the light absorption layer, maximize light absorption by no grid lines on the front side and multi-layered anti-reflection film and increase the intensity of incident light and short-circuit current by sub-micro texture.In the photoelectric conversion layer, reduce compounding and increase open-circuit voltage by tunneling oxidation passivation and multi-layer passivation, and increase carrier lifetime and open-circuit voltage by hydrogen passivation.In the electrical transmission layer, ensure stable current transmission by positive and negative connections on the back side.

Because of the issue of light leakage in the gaps between he solar cells in double-glass modules, LONGi generally uses glazed semi-tempered glass for the backside panel of the double-glass module, with a glazed layer formed into grids where the cells are placed. Because the requirement for accuracy and shading of the glazed layer on the back panel of the cell should be reduced, a certain amount of light leakage is allowed in the industry, without any effect on the quality and energy yield of the product. The inconsistency in light transmittance on the back panel of the single-glass module is caused by differences in light transmittance caused by variations in each model of the back panel of the module. However, when the quality of the back panel meets the certification criteria, there will be no effect on energy yield. Agents will preferentially load the same batch of modules and ship them to the downstream customers.

Customized module are available to meet the special demands of customers, and are in compliance with the relevant industrial standards and test conditions. During the sales process, our salespersons will inform customers of the basic information of the ordered modules, including mode of installation, conditions of use, and the difference between conventional and customized modules. Similarly, agents will also inform their downstream customers of the details about the customized modules.